Got three sections of the right wing sheeting in place, I'm getting there...

Announcement

Collapse

No announcement yet.

Right wing sheeting

Collapse

X

-

Right wing sheeting

You do not have permission to view this gallery.

This gallery has 3 photos.Dave Bottita The Desert Bearhawk

Project Plans #1299

N1208 reserved www.facebook.com/desertbearhawk/Tags: None

-

Dave, you continue to inspire many of us that have yet to "get off the ground" and out of our collective Lazy Boy's to start our projects.

Once I try a LSA on for fit in January, if all goes as planned, metal cutting shall commence here in AZ.

Nice work!

John Massaro

Plans Building LSA - 091

Arizona

-

Thanks John! It's a long slow trip scratch building! Dave Bottita The Desert Bearhawk

Dave Bottita The Desert Bearhawk

Project Plans #1299

N1208 reserved www.facebook.com/desertbearhawk/

Comment

-

Dave, You wing looks great. It is interesting seeing the small differences between your 4 place and my patrol. I am at a similar place in my wing building. I am interested in how you did your match drilling of the skins. I ended up back drillng them all because on the patrol skins they only cover 2 bays on the two outboard skins and three on the next 2 bays. Eric's method would not work there. I ended up drilling all the holes on the outboard skin the I installed the next inboard skin and drilled all the holes except the overlap holes. I then back drilled the center rib skins. I the removed all the clecos from the bottom side of the two skins and back drilled the nose ribs. I the re-clecoed the nose bottoms and secured the bottom to the spar with clamps. also also secured the bottom nose skins together with tape and the un clecos the top side of both skins and lifted the skins and back drilled these.

Both times when I back drilled I was able to align the rib hole with the skin hole with the drill bit then my wife would hold a wood block against the outside skin. I would drill the she would cleco and we would repeat.. It worked very well

I also discovered that cutting the skins with my circular saw on a track and a triple chip blade made simple work of cutting the skins. They cut like butter. I was even able to use the track saw for final trimming and only had to cut the last 4" around the bend by hand. I have a 14' track so I could cut the 12' skins in about 30 seconds. I will have to send you a video of it.

lastly I have built up a landing light for the leading edge of the tip. It was inspired by the duck works landing light kit for the RV. I will have a 10deg spot landing light and a 30deg taxi light in each tip. The mount allows about 15-20 deg of up down and side to side adjustment of each LED light. I do have full sized drawing of the parts of anyone is interested. There would need to be slight changes for a 4 place.John Snapp (Started build in Denver, CO) Now KAWO -Arlington Washington Bearhawk Patrol - Plans #255 Scratch built wing and Quickbuild Fuselage as of 11/2021. Working on skinning the left wing! -Ribs : DONE -Spars: DONE, Left wing assembly's: DONE., Top skins : DONE YouTube Videos on my building of patrol :https://m.youtube.com/user/n3uw

Comment

-

Glad to know others do this tooOriginally posted by N3UWI also discovered that cutting the skins with my circular saw on a track and a triple chip blade made simple work of cutting the skins. They cut like butter. I was even able to use the track saw for final trimming and only had to cut the last 4" around the bend by hand. I have a 14' track so I could cut the 12' skins in about 30 seconds. I will have to send you a video of it. I tried my track saw on a whim when I started skinning.......and it worked like a charm! I had a 60 tooth Freud blade in my saw and it leaves a beautiful cut, takes just a light pass with a deburring disc to clean it up. Especially makes cutting the .032 panel easy.

I tried my track saw on a whim when I started skinning.......and it worked like a charm! I had a 60 tooth Freud blade in my saw and it leaves a beautiful cut, takes just a light pass with a deburring disc to clean it up. Especially makes cutting the .032 panel easy.

Comment

-

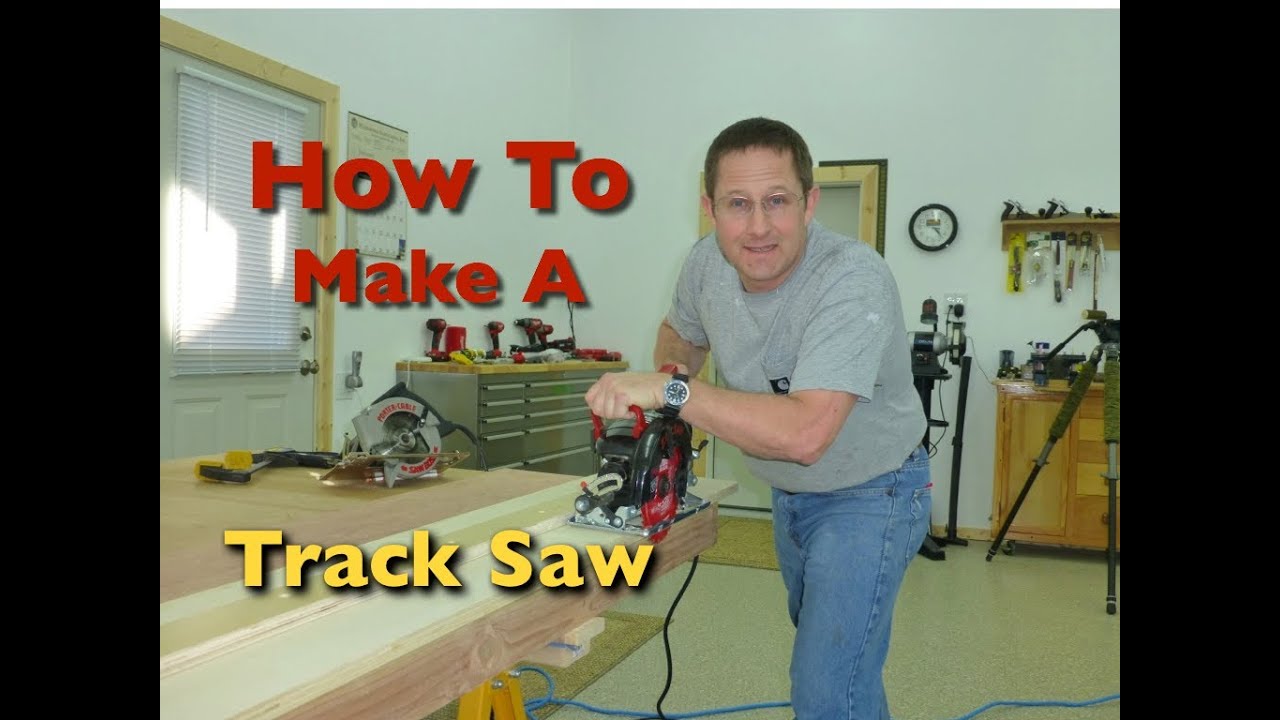

It's basically an aluminum extrusion that your circular saw rides on. It provides much more stability than using a 2x4, but same concept. I've got the one made Eurekazone, and have found it very valuable when cutting the big sheets during wing skinning.Originally posted by bestbearhawk1231 View PostOut of curiosity, what is a track saw? Similar to a circular saw and using a 2x4 for a fence?

Comment

-

A track saw is basically a circular saw that runs down a track. It is possible for a circular saw against a 2x4 to pick up the thin aluminum and cause a mess. the track pushed down on the aluminum for the entire length. I have had a Festool circular saw on a 12' track that I have had for years. They are a bit pricy. You can build one for about $10 using any standard circular saw and a GOOD fine tooth triple chip tooth carbide blade (I think mine is a 56 tooth blade). Here is a good video on how to make one.Originally posted by bestbearhawk1231 View PostOut of curiosity, what is a track saw? Similar to a circular saw and using a 2x4 for a fence?

#howto #Tracksaw #woodworking How To Build A Track Saw. This simple cheap way of building a Home or job site track Saw work great! You can make one for less...

#howto #Tracksaw #woodworking How To Build A Track Saw. This simple cheap way of building a Home or job site track Saw work great! You can make one for less...

John Snapp (Started build in Denver, CO) Now KAWO -Arlington Washington Bearhawk Patrol - Plans #255 Scratch built wing and Quickbuild Fuselage as of 11/2021. Working on skinning the left wing! -Ribs : DONE -Spars: DONE, Left wing assembly's: DONE., Top skins : DONE YouTube Videos on my building of patrol :https://m.youtube.com/user/n3uw

Comment

-

I have really fallen in love with the ease of cutting alumi pinup sheet with a circular saw. I originally wanted a shear but I am glad I did not get one. The track saw is just so easy and leaves a better edge. The secret is the proper blade ( fine tooth triple chip carbide. Typically they will say good for cutting nob-ferrous metals). Also keeping the aluminum sheet flat and sandwitched fight between the cutting table below and the track. The homemade unit will work just as well as the festool.John Snapp (Started build in Denver, CO) Now KAWO -Arlington Washington Bearhawk Patrol - Plans #255 Scratch built wing and Quickbuild Fuselage as of 11/2021. Working on skinning the left wing! -Ribs : DONE -Spars: DONE, Left wing assembly's: DONE., Top skins : DONE YouTube Videos on my building of patrol :https://m.youtube.com/user/n3uw

Comment

-

John, Getting ready to order a blade for a homebuilt track saw for the spars. How would one of these work or do you recommend another? Cheaper?

http://www.ebay.com/itm/Tenryu-AC-18...-/251160181989

Doug

Last edited by DRLPatrol; 02-27-2015, 03:07 PM.Scratch building Patrol #254

Comment

-

The Tenryu aluminum blade is an excellent choice. I have one on my chop saw and it works great.John Snapp (Started build in Denver, CO) Now KAWO -Arlington Washington Bearhawk Patrol - Plans #255 Scratch built wing and Quickbuild Fuselage as of 11/2021. Working on skinning the left wing! -Ribs : DONE -Spars: DONE, Left wing assembly's: DONE., Top skins : DONE YouTube Videos on my building of patrol :https://m.youtube.com/user/n3uw

Comment

-

I do not have experience with that manufacturer but reviews on Amazon have good ratings. It would probably be fine, You can also extend the life of a blade of you rub Boelube (The hard white waxy version) on the teeth before you cut the aluminum.John Snapp (Started build in Denver, CO) Now KAWO -Arlington Washington Bearhawk Patrol - Plans #255 Scratch built wing and Quickbuild Fuselage as of 11/2021. Working on skinning the left wing! -Ribs : DONE -Spars: DONE, Left wing assembly's: DONE., Top skins : DONE YouTube Videos on my building of patrol :https://m.youtube.com/user/n3uw

Comment

Comment