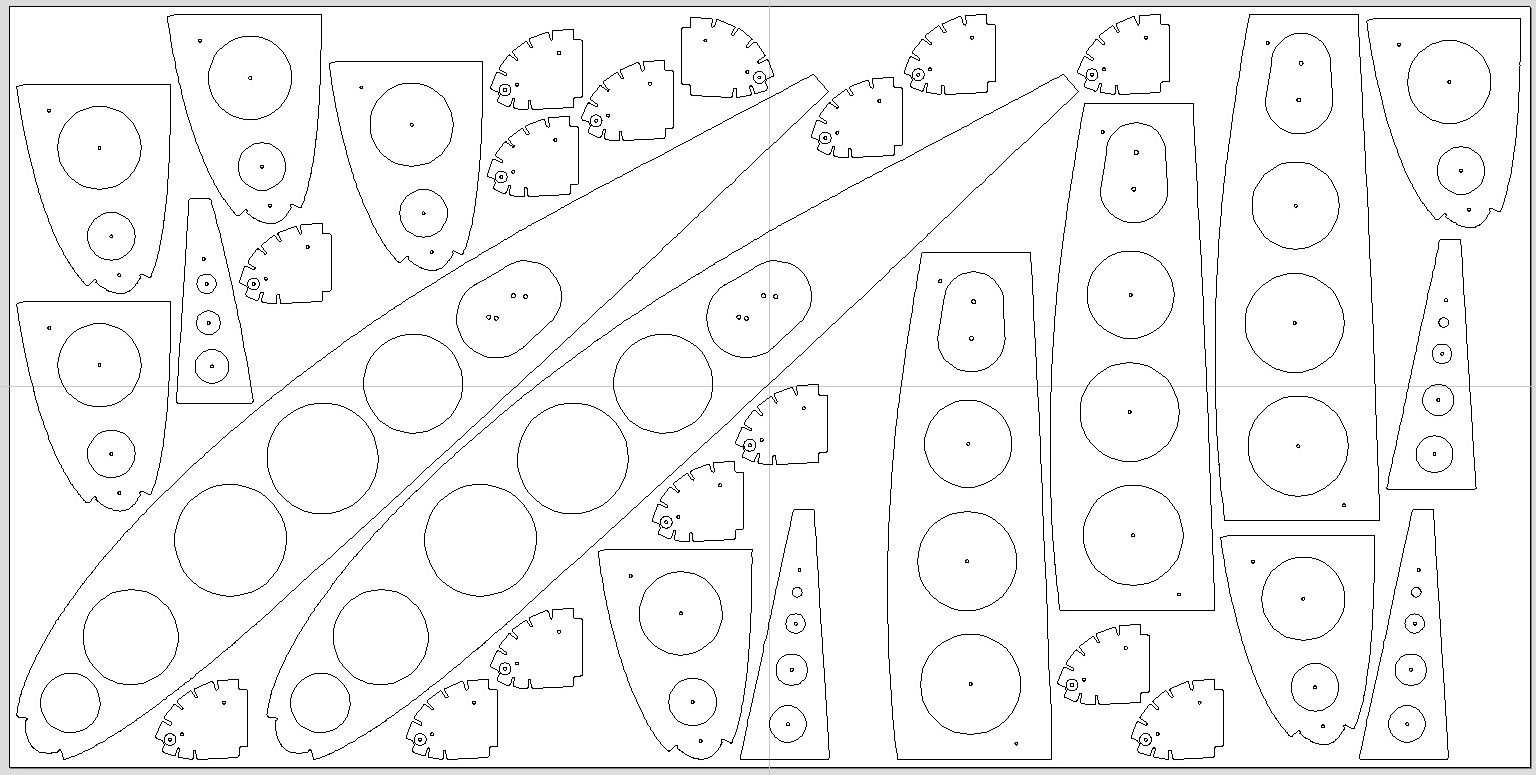

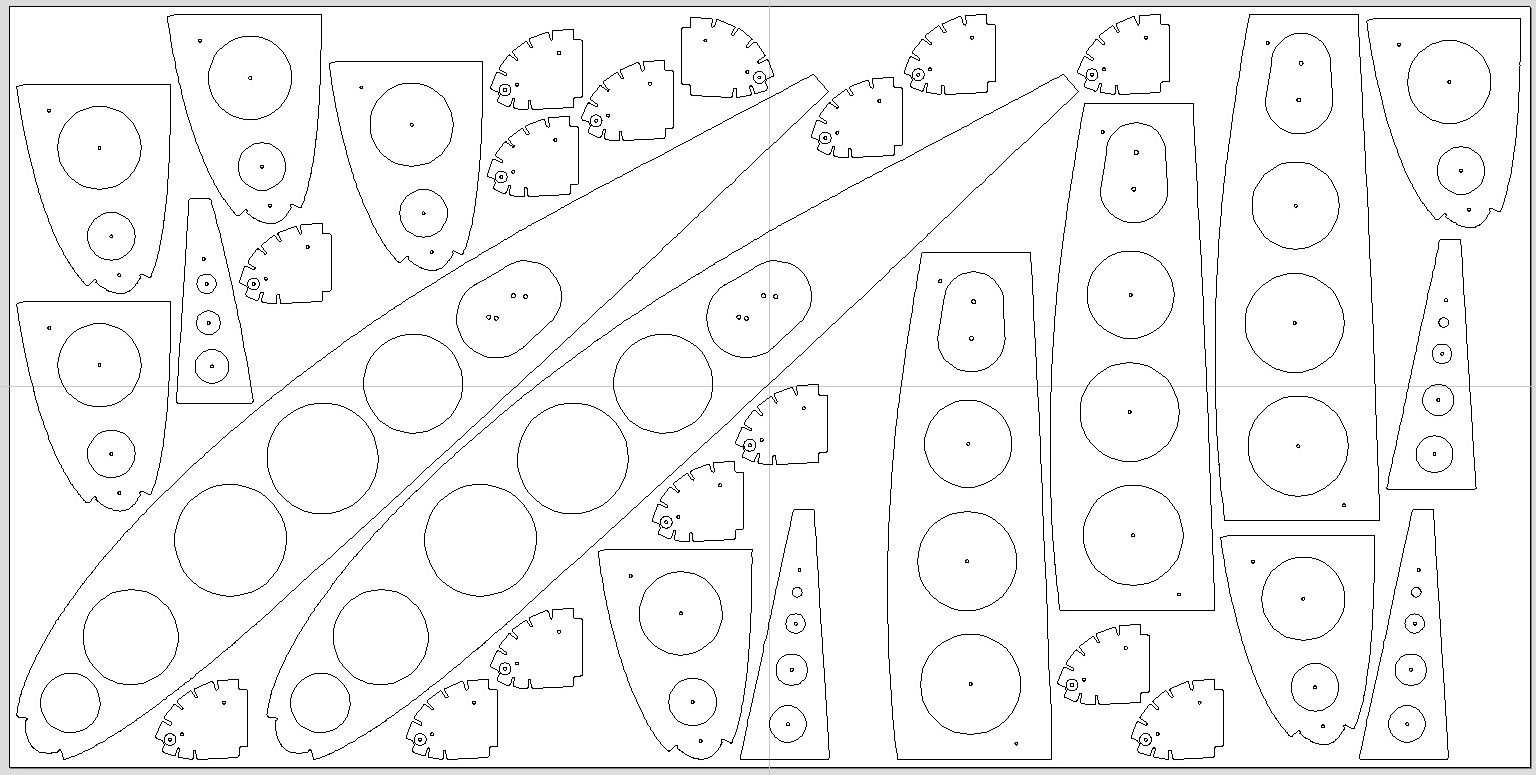

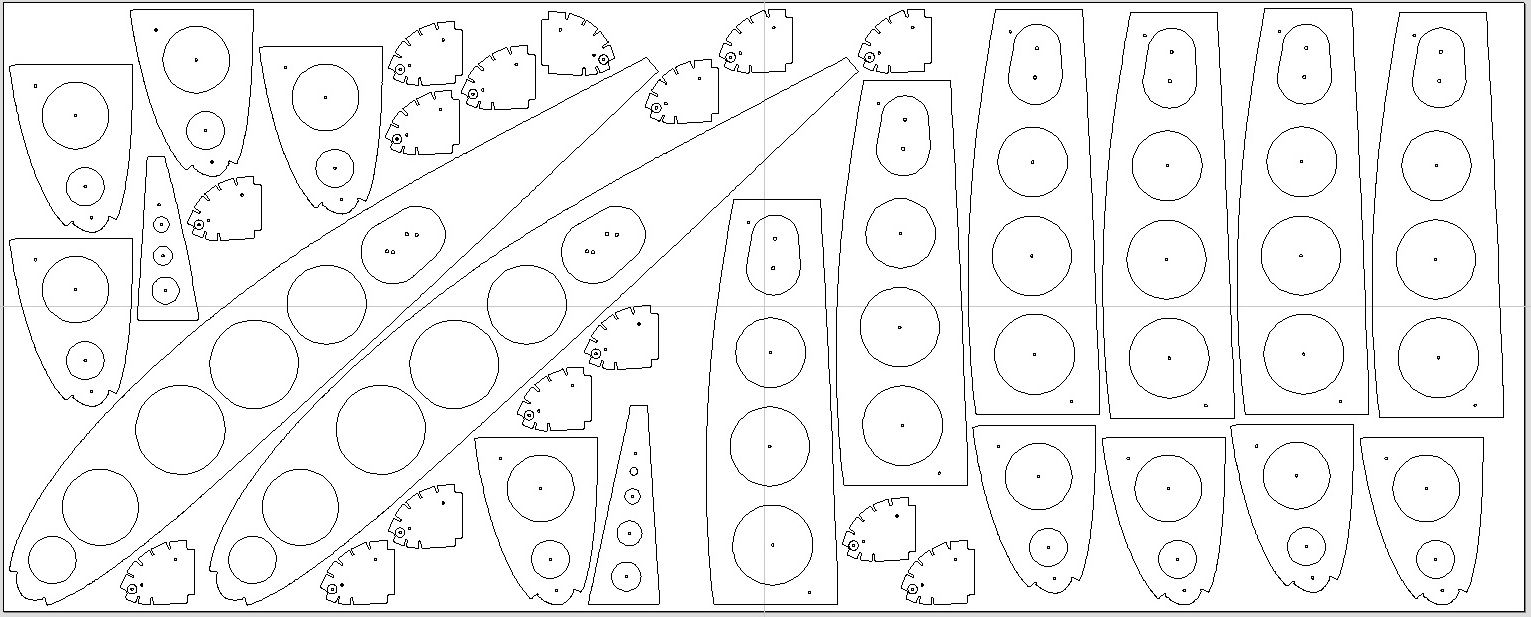

Others have asked so I decided to take the time to do a couple of layouts for people. There is a 1/2" between parts so its not super tightly nested but it should be easy to do the rough cut outs before routing to size. Right now I only have the .025 sheets done.

4x8 .025 sheet nesting

Enjoy.

Dan Patrol #243

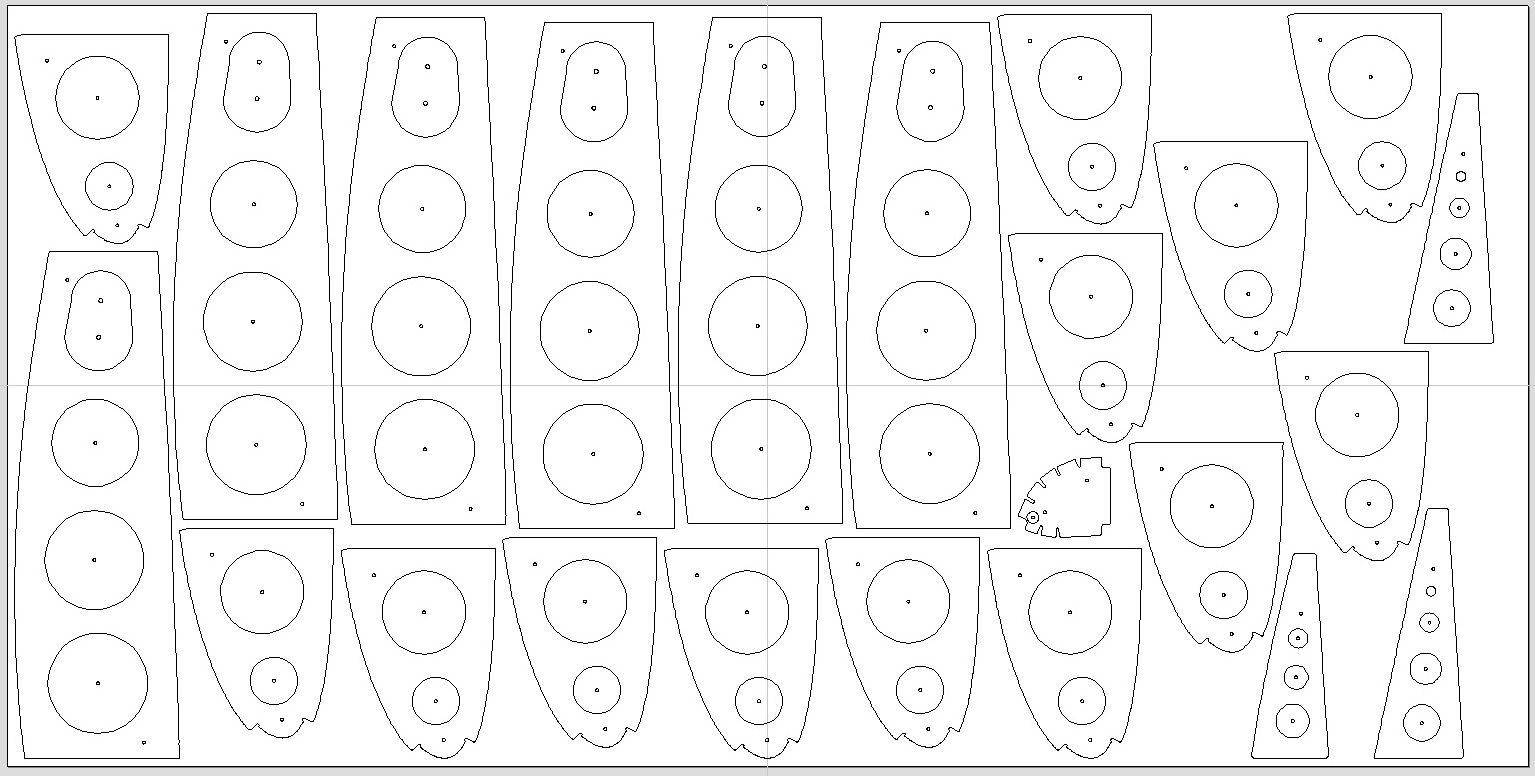

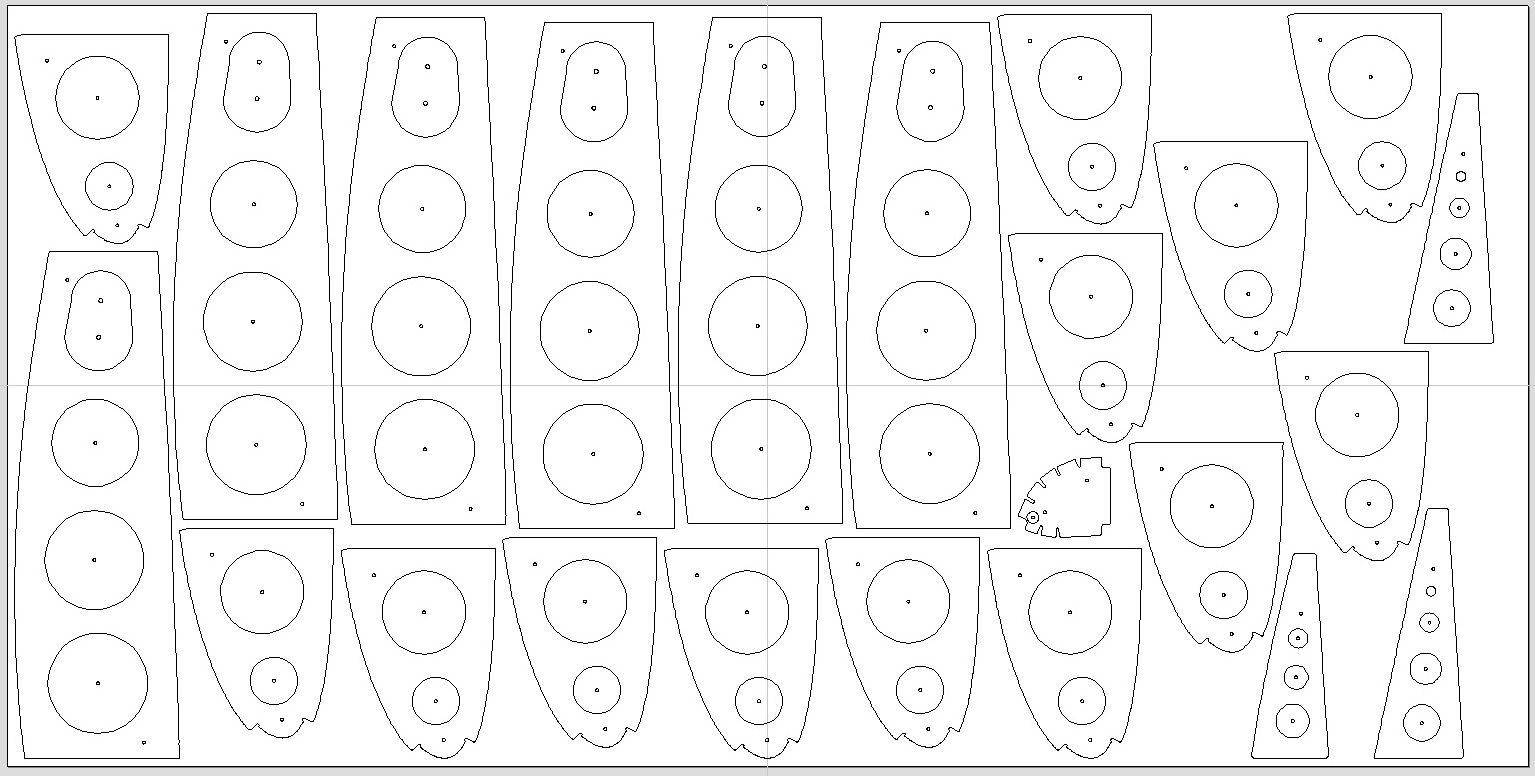

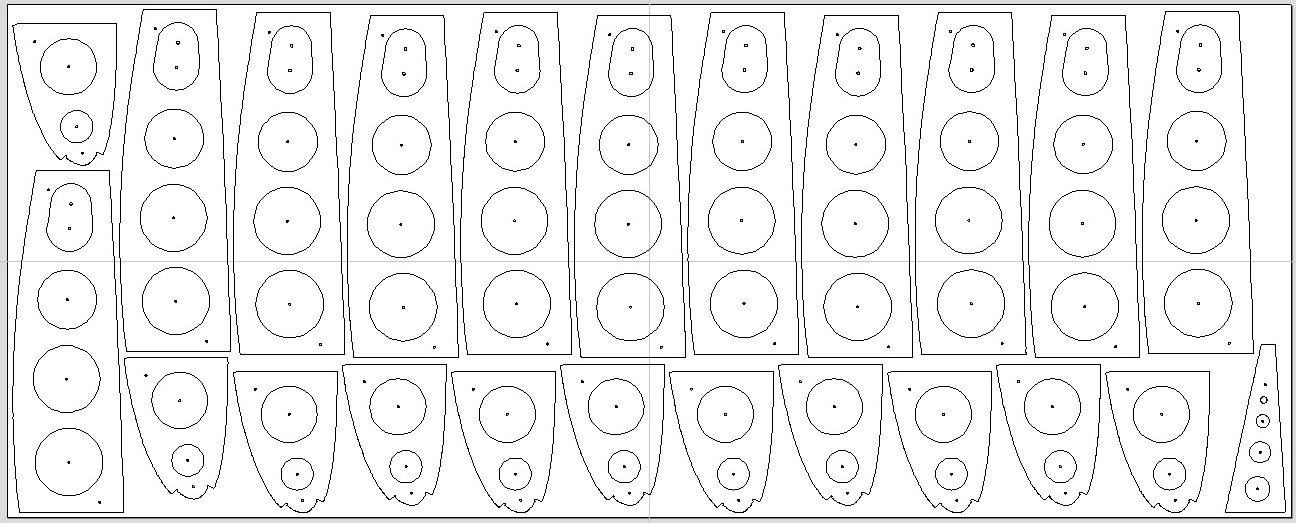

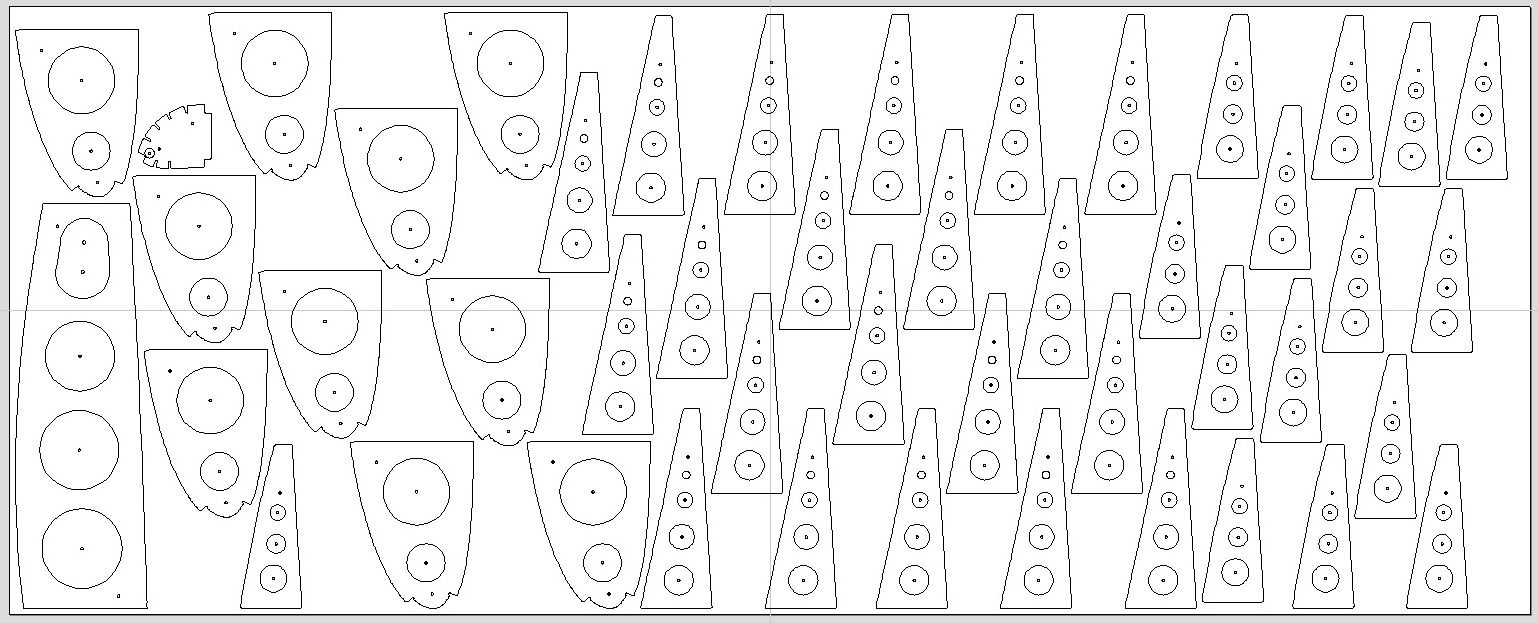

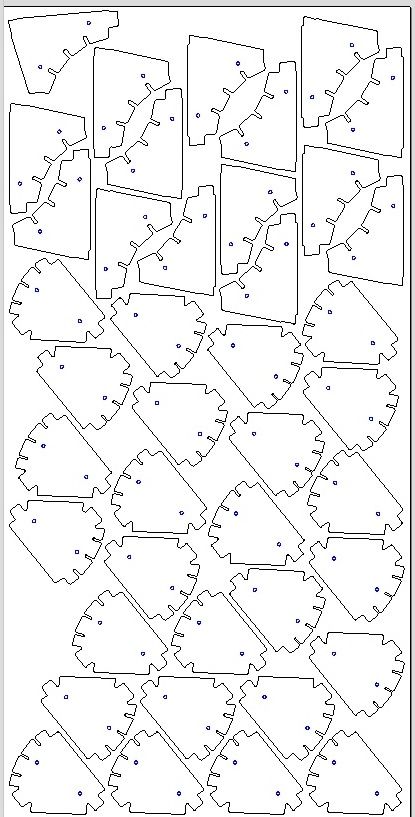

4x8 .025 sheet nesting

Enjoy.

Dan Patrol #243

Comment