Announcement

Collapse

No announcement yet.

Bearhawk STOL mods

Collapse

X

-

Q1: About 8 to 10 degrees improvement could be expected, based on the results for other aircraft.

Q2: VGs make a big difference throughout the whole approach. They transform the wing when installed properly. I have the benefit of flying two sister-ship Bearhawk 4 places, to compare the differences with and without.

-

Regarding AoA flap bias, for simplicity sake, in GA, just set it to stall with flaps full, which will be a lower AoA than with flaps retracted. If you approach the calibrated critical angle of attack while clean, you'll then have a healthy buffer before an actual stall.Originally posted by kestrel View Post

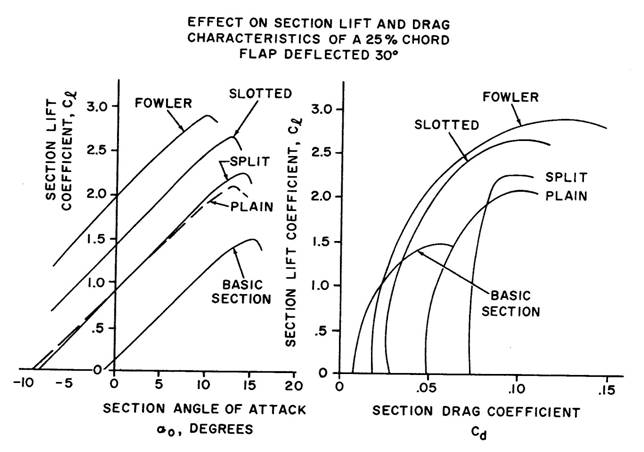

The only thing with the fowlers is you'll have a very large difference in the critical angle of attack vs a plain or slotted. Where it's 2-4 degrees for the latter, the former looks like it could be 5-7 degrees according to the graph from the naval aviators book. 7 degrees is massive(considering an aircraft usually has a longitudinal flight envelope of 0ish to 15ish degrees AoA), and might result in stall warnings at rather high airspeeds. Might be worth contacting the manufacturer of your AoA system to see if flap bias is programmable.... if you have fowlers.Last edited by zkelley2; 09-21-2019, 04:44 PM.

-

That sounds like a detail I would have discovered right after I installed slotted flaps.

- Likes 1

Leave a comment:

-

Started following this thread. Very interesting. I'd like to put slotted flaps on our BH but haven't figured out how to have a hinge by the cargo door.

- Likes 2

Leave a comment:

-

Most likely yes. More flap usually results in a higher max lift coefficient, but at a lower angle of attack.Originally posted by whee View PostQuestion: Will slotted flaps allow for a more nose down approach and touchdown when flying at minimum airspeed?

No. VG's allow flying to a higher angle of attack but normally produce the same lift for the same AoA.Second question: Will VGs allow the plane to fly at a slower speed for a given AOA when in the slow flight regime?

Leave a comment:

-

I am really hoping these flaps work out on a BH because I am interested. Controllability might be a huge issue, and not just running out of elevator authority at low speed. The BH has comparatively large area flaps, so they will be very effective, but that might include a lot more unpleasantness as well. Huge pitch changes can happen in only 5-15 knots of speed change.

A go around could get interesting really quickly, and not in a good way. Most big airplanes have huge and very effective Trimmable Horizontal Stabilizers that can handle the change in CP quickly. With the flaps down some of them make the trim motors run much more quickly to help deal with it. But it is always an issue. The second step of every go around is raising the flaps (to less than half). Part of the reason is to reduce drag. A big part is to reduce the pitch change from when accelerating.

I hope they work out great.Last edited by svyolo; 09-20-2019, 11:11 AM.

Leave a comment:

-

Trailing edge devices facilitate a lower nose on approach - the more efficient they are (ie: slotted vs straight), the lower the nose. Have a look at the video here https://youtu.be/NZ9I61UGwcg for a comparison of deck angles on a Super Cub with stock flaps and Keller flaps.Originally posted by whee View PostQuestion: Will slotted flaps allow for a more nose down approach and touchdown when flying at minimum airspeed?

I’m beginning to understand why others have wanted a Fowler flap or a semi-Fowler like a Cessna. When practicing max performance landings I touchdown in a very nose high attitude which someday will result in something broken in the tail.

Second question: Will VGs allow the plane to fly at a slower speed for a given AOA when in the slow flight regime?

To me, safety is the most important benefit to slotted flaps. While it is dramatic to see a slow approach at a high deck angle and slow airspeed, the pilot usually is blind to the landing zone in the final stages of the approach. In the Airframes PSTOL video, it is clear that the deck angle is substantially lower with the slotted flaps compared to straight flaps.

A nice additional benefit is a slower approach speed leading to a shorter landing roll.

VG’s (and other leading edge devices like slats and slots) will lower the stall speed at high AOA by energizing the flow over the leading edge and keeping it attached for more of the wing chord.

Leave a comment:

-

Question: Will slotted flaps allow for a more nose down approach and touchdown when flying at minimum airspeed?

I’m beginning to understand why others have wanted a Fowler flap or a semi-Fowler like a Cessna. When practicing max performance landings I touchdown in a very nose high attitude which someday will result in something broken in the tail.

Second question: Will VGs allow the plane to fly at a slower speed for a given AOA when in the slow flight regime?

Leave a comment:

-

I agree this is a concern. However, a Bearhawk with plain flaps pitches down when flaps are deployed while a Cessna with slotted flaps pitches up. The plain flap produces less down-wash over the tail than a slotted flap. There is a chance that the increased angle of flow over the tail will counter balance the increased pitching moment of the wing and the problem will correct itself. I can't wait to see results of a test as we won't know until that happens.Originally posted by Battson View PostThe issue (big unknown) is the pitching moment. Bob has advised that the tail may not be large enough to overcome the increased nose-up pitching forces created by the double slotted flaps. The ultimate solution will be larger tail wings, if gap seals / VGs / greater control deflection don't solve it first.

- Likes 2

Leave a comment:

-

The speed range of the BH range is the equal of anything. But that comes with limitations at both ends of the speed spectrum.Twitchy at the high end, run out of control authority at the low end. I bought the kit because of the compromise.

How much would I pay for a 4 mph reduction in landing speed? If I can't control it, zero. If it works, I will get in line, price dependent.

- Likes 1

Leave a comment:

-

Someone is doing this at the moment.Originally posted by Shopperly View Post

The current price of the double slotted experimental flap from Performance STOL/Airframes is between $6400 and $8400 depending on the number of hangars required. Has anyone taken the leap and built or modified a Bearhawk wing to accept this system? Is it possible to mount these on a QB wing kit?

The design will allow Airframes AK to offer a standard bolt-on solution for Bearhawk aircraft wings, hopefully they do.

The issue (big unknown) is the pitching moment. Bob has advised that the tail may not be large enough to overcome the increased nose-up pitching forces created by the double slotted flaps. The ultimate solution will be larger tail wings, if gap seals / VGs / greater control deflection don't solve it first.

- Likes 1

Leave a comment:

-

The current price of the double slotted experimental flap from Performance STOL/Airframes is between $6400 and $8400 depending on the number of hangars required. Has anyone taken the leap and built or modified a Bearhawk wing to accept this system? Is it possible to mount these on a QB wing kit?Originally posted by Battson View PostI've gone as far as designing flap tracks for the Bearhawk, for a true Fowler system. It was based on the tracks used by the Sherpa Turbine. They are expensive to have machined, so I started looking deeper before progressing.

The problem I found was the bending moment / torque on the rear spar. This would need more steel braces between spars to avoid cracking the wing skin from fatigue. That work would require opening the wing skin. Too invasive for a "working" plane, it would be out of action for many months!

The beauty of the slotted flap or double slotted flap is they can be retrofitted with just a few simply mods to the trailing edge of the wing (non-structural), plus a new hinge which can be bolted on. They also create less torque on the rear spar.

The price of the Airframes Alaska flaps is high, but that's just aviation. I hope the tailwings are large enough with VGs and gap seals installed. Alternatively, they could easily be replaced.

Leave a comment:

-

Yes I mixed up acceleration and velocity. My bad. I was thinking same as dropping a plane 10 ft off the ground, but that give the right average velocity - not the right instantaneous velocity at touchdown.

The correct analogy is dropping a plane from 5 ft off the ground. Still a hard impact, but not a "serious crash".

Leave a comment: