Hello everyone,

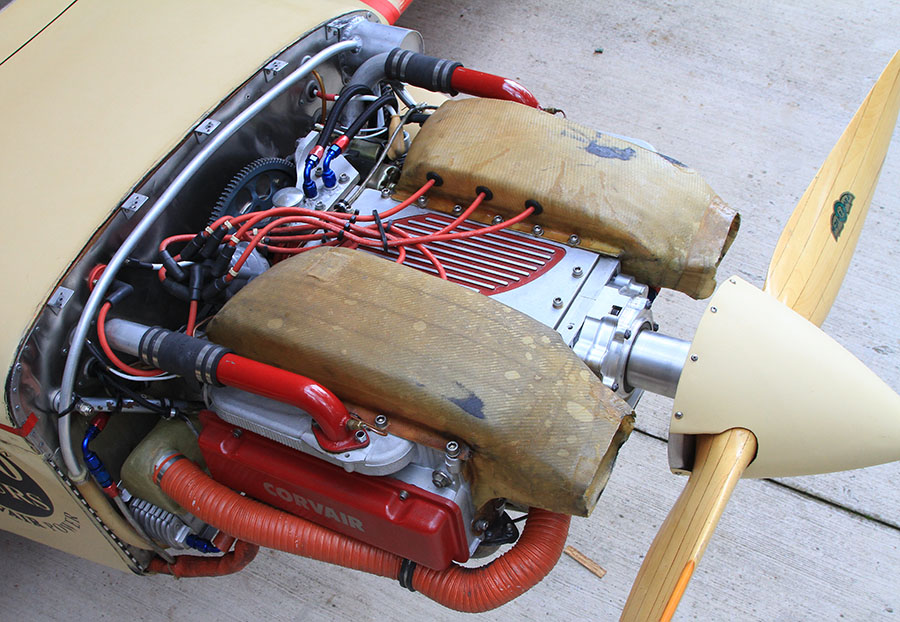

Just started this new topic in the hopes to centralize Corvair Engine Installations in the LSA. Seems like there is a bit of interest and several builders, myself included, rebuilding Corvair's for the installation on the Bearhawk LSA. Here is a few links that I have found thus far. Any more info, the more the better. Bring it on and if you feel like contributing to this topic page here, great and we thank you in advance!

These links have been previously posted, but just in case here they are once more. Cheers, Willy T.

​​​​​​https://flycorvair.net/2016/10/28/28...sa-now-flying/

​​​​​​https://flycorvair.net/2013/10/04/co...-bearhawk-lsa/

..also if someone is interested in the Yamaha RX1 conversion for their LSA, we do have one flying here in an FAT Avid. But that would make for another topic yet, lets keep it to Corvair's on this page.

Just started this new topic in the hopes to centralize Corvair Engine Installations in the LSA. Seems like there is a bit of interest and several builders, myself included, rebuilding Corvair's for the installation on the Bearhawk LSA. Here is a few links that I have found thus far. Any more info, the more the better. Bring it on and if you feel like contributing to this topic page here, great and we thank you in advance!

These links have been previously posted, but just in case here they are once more. Cheers, Willy T.

​​​​​​https://flycorvair.net/2016/10/28/28...sa-now-flying/

​​​​​​https://flycorvair.net/2013/10/04/co...-bearhawk-lsa/

..also if someone is interested in the Yamaha RX1 conversion for their LSA, we do have one flying here in an FAT Avid. But that would make for another topic yet, lets keep it to Corvair's on this page.

Comment