I am leaning towards getting a new engine over a rebuilt one. What new Lycoming O-360 do you order if you want a fairly standard and simple installation? There is good information for the 4-Place but not so much for the Patrol.

My starting point are the Vans order forms for Thunderbolts and OEMs EXP engines:Also what's the advantage of the more expensive Thunderbolt line other than some paint and polishing?

So far I have the following specs:

- mount: dynafocal type I

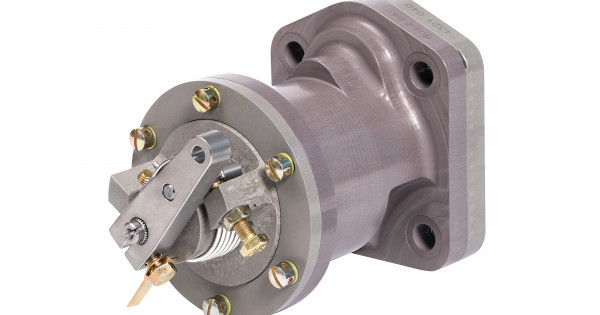

- CS prop provision

- 8.5:1 compression (90 autogas)

- wide deck (standard for new engines)

- parallel valve (better fit)

- non-mass-balanced crankshaft (lighter)

- ignition: E-Mags (would prefer the fuel savings and less maintenance)

Mark Goldberg if you read this, I would be curious what's your take. I though of posting it here over asking you directly. I feel it's a recurring question.

Comment