I really have no idea how this managed to occur, but worth knowing about... If your hinge pocket covers don't go all the way to the front of the flap - then you have a problem waiting to happen.

We had one of our hinge pocket covers, somehow, jam into the trailing edge of the wing top skin. Our pocket covers were short enough that their leading edge passes beyond the trailing edge of the top wing skin, when the flap is fully deployed.

Now, the hinge pocket cover didn't come loose. All 4 screws were in tight and stayed tight. The top skin somehow flexed down into the path of the hinge pocket cover. Yes, it is hard to conceive how that can happen - I can only assume it was the high loading on the wing causing the skin to move. With the wing sitting with only self-weight (when the aircraft is sitting on the ground), there is perhaps a 1/4" or more clearance.

This all took place when I "popped" the flap to take-off from a small airstrip in a strong gusty wind, the flap never retracted past the 3rd (and a half) notch due to the jam. Practically full flap. I can only imagine that the wing skin flexed at the same moment due to a strong gust of wind we experienced (we really leaped into the air when I popped flap).

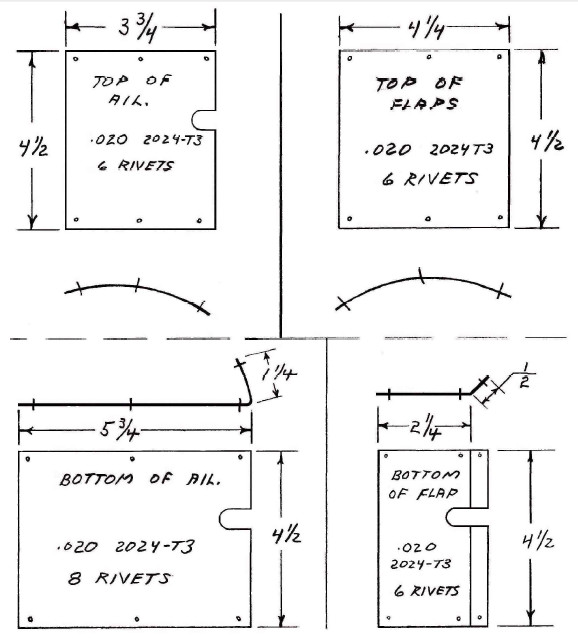

The jam did considerable cosmetic damage to the top skin of the wing. It was the pocket where the skins join which jammed, to the combined thickness of the two sheets of 0.025" Aluminium, plus stiffener section, resisted any more serious damage. I was amazed the four small 3/32" self-tapping screws holding the flap hinge pocket cover in place didn't give way, nor did the 0.025" cover itself. I am considerably impressed that this light structure could support the flap at the airspeed we achieved (about 75 KIAS) before we found the problem.

Naturally I have repaired the damaged metal, removed the crack initiation sites, and smoothed all rough edges to complete a basic field repair. I may consider adding a doubler when I return to home-base. My fear was a crack starting in the under-lapped skin, and moving rivet to rivet unseen beneath the overlapped skin - so I have been very careful to sand and polish everything smooth with Scotchbright. We removed a number of rivets to enable access.

I will certain be redesigning all the flap hinge pocket covers, so they can slide under the top wing skin in the event the two make contact.

One very interesting fact:

The Bearhawk can easily be controlled with 1 flap fully deployed and the other fully retracted, even as fast as 75 KIAS. The control inputs necessary to remain straight and level (or climbing at full power), are only marginally out of balance - just enough that you would certainly notice something is wrong. You most definitely are not fighting for aileron authority, as many would have you believe, all that is required is just a little rudder and a little opposite aileron to continue in balanced flight.

We had one of our hinge pocket covers, somehow, jam into the trailing edge of the wing top skin. Our pocket covers were short enough that their leading edge passes beyond the trailing edge of the top wing skin, when the flap is fully deployed.

Now, the hinge pocket cover didn't come loose. All 4 screws were in tight and stayed tight. The top skin somehow flexed down into the path of the hinge pocket cover. Yes, it is hard to conceive how that can happen - I can only assume it was the high loading on the wing causing the skin to move. With the wing sitting with only self-weight (when the aircraft is sitting on the ground), there is perhaps a 1/4" or more clearance.

This all took place when I "popped" the flap to take-off from a small airstrip in a strong gusty wind, the flap never retracted past the 3rd (and a half) notch due to the jam. Practically full flap. I can only imagine that the wing skin flexed at the same moment due to a strong gust of wind we experienced (we really leaped into the air when I popped flap).

The jam did considerable cosmetic damage to the top skin of the wing. It was the pocket where the skins join which jammed, to the combined thickness of the two sheets of 0.025" Aluminium, plus stiffener section, resisted any more serious damage. I was amazed the four small 3/32" self-tapping screws holding the flap hinge pocket cover in place didn't give way, nor did the 0.025" cover itself. I am considerably impressed that this light structure could support the flap at the airspeed we achieved (about 75 KIAS) before we found the problem.

Naturally I have repaired the damaged metal, removed the crack initiation sites, and smoothed all rough edges to complete a basic field repair. I may consider adding a doubler when I return to home-base. My fear was a crack starting in the under-lapped skin, and moving rivet to rivet unseen beneath the overlapped skin - so I have been very careful to sand and polish everything smooth with Scotchbright. We removed a number of rivets to enable access.

I will certain be redesigning all the flap hinge pocket covers, so they can slide under the top wing skin in the event the two make contact.

One very interesting fact:

The Bearhawk can easily be controlled with 1 flap fully deployed and the other fully retracted, even as fast as 75 KIAS. The control inputs necessary to remain straight and level (or climbing at full power), are only marginally out of balance - just enough that you would certainly notice something is wrong. You most definitely are not fighting for aileron authority, as many would have you believe, all that is required is just a little rudder and a little opposite aileron to continue in balanced flight.

Comment