Yesterday I experienced a broken tail wire while inflight. I did not know the tail wire broke until after I was shut down and began refueling…

The incident happened while in level cruise flight and on auto pilot (2 axis). There was a sudden “pop”. My nose pitched slightly down and to the left. I had no idea what had just happened.

I immediately disconnected AP and reduced power slightly. The airplane felt ok as I touched the control stick left, right, up & down a few times. I changed course and turned to my destination, about 15 miles away (KIPJ). With the wings level I turned the AP on again, still trying uncover what happened. The AP pitch began hunting to maintain altitude. It was very minimal, but the nose was ever so slightly nodding. Even with the AP off, I could not trim and hold altitude. I entered the downwind and made gentle turns to base and final. With 3 notches of flaps, it was one of my best landings!

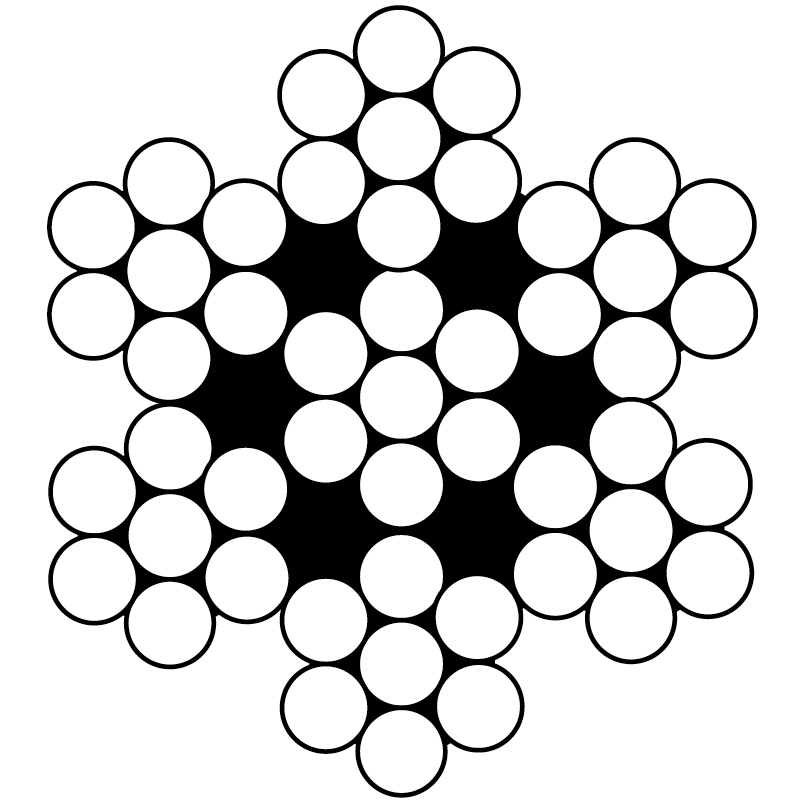

I taxied over to the fuel pumps and found my right upper streamlined flying wire had broken. See the attached picture.

Mark and I spoke on the phone. He stated this has occurred before, in the same location on a LSA. But never on a 4 place that he is aware of.

This left me stranded at KIPJ, and Mark is expediting a new wire to me now.

FOR DISCUSSION….

Mark mentioned harmonics as a cause to this failure. I’ve read a few threads here about vibration of streamlined H stab struts and tail wires, and broken tail strut threads.

https://bearhawkforums.com/forum/saf...321-tail-wires

I’m curious what others think about the overall direction I am considering with the tail/flying wires.

I am beginning to believe that streamlined wires are more prone to vibration over round flying wires. And the drag reduction benefit of streamline wires over round wires does not outweigh the failure potential.

I am not sure that I could ever position a fixed streamlined wire into the wind such that it would never vibrate. There could be a point in deck angle where no vibration occurs, but a slight trim adjustment will change the AOA of the wire (up or down) now creating an adverse vibration. I cannot imagine this occurring with a round wire.

As I mentioned, Mark will be sending me a new replacement streamlined wire to get me flying again, and to fulfill my Oshkosh obligation which I am very much looking forward to!

I wonder if I can dampen the streamline tail wires for the interim...

But long term, I am considering going to round wires (or possibly cables) only for the added safety aspect. If drag ever becomes a concern, I may consider fairing the round wires using something like this. https://antisplataero.com/products/u...ine-fairing-14

I’ve also read some discussion here from Isilverone and others about using velcro strips, or turbulator tape on the bottom of the H stab struts to reduce vibration. I will be looking into this as well with my new found sensitivity to tail vibration and cure for any and all vibration.

I would also like to know more about swagged cables for tail wires. Especially for the uppers and as a replacement for steamlined wires. If anyone has experience making and using these, please comment!

Thank you so much!

Rob

The incident happened while in level cruise flight and on auto pilot (2 axis). There was a sudden “pop”. My nose pitched slightly down and to the left. I had no idea what had just happened.

I immediately disconnected AP and reduced power slightly. The airplane felt ok as I touched the control stick left, right, up & down a few times. I changed course and turned to my destination, about 15 miles away (KIPJ). With the wings level I turned the AP on again, still trying uncover what happened. The AP pitch began hunting to maintain altitude. It was very minimal, but the nose was ever so slightly nodding. Even with the AP off, I could not trim and hold altitude. I entered the downwind and made gentle turns to base and final. With 3 notches of flaps, it was one of my best landings!

I taxied over to the fuel pumps and found my right upper streamlined flying wire had broken. See the attached picture.

Mark and I spoke on the phone. He stated this has occurred before, in the same location on a LSA. But never on a 4 place that he is aware of.

This left me stranded at KIPJ, and Mark is expediting a new wire to me now.

FOR DISCUSSION….

Mark mentioned harmonics as a cause to this failure. I’ve read a few threads here about vibration of streamlined H stab struts and tail wires, and broken tail strut threads.

https://bearhawkforums.com/forum/saf...321-tail-wires

I’m curious what others think about the overall direction I am considering with the tail/flying wires.

I am beginning to believe that streamlined wires are more prone to vibration over round flying wires. And the drag reduction benefit of streamline wires over round wires does not outweigh the failure potential.

I am not sure that I could ever position a fixed streamlined wire into the wind such that it would never vibrate. There could be a point in deck angle where no vibration occurs, but a slight trim adjustment will change the AOA of the wire (up or down) now creating an adverse vibration. I cannot imagine this occurring with a round wire.

As I mentioned, Mark will be sending me a new replacement streamlined wire to get me flying again, and to fulfill my Oshkosh obligation which I am very much looking forward to!

I wonder if I can dampen the streamline tail wires for the interim...

But long term, I am considering going to round wires (or possibly cables) only for the added safety aspect. If drag ever becomes a concern, I may consider fairing the round wires using something like this. https://antisplataero.com/products/u...ine-fairing-14

I’ve also read some discussion here from Isilverone and others about using velcro strips, or turbulator tape on the bottom of the H stab struts to reduce vibration. I will be looking into this as well with my new found sensitivity to tail vibration and cure for any and all vibration.

I would also like to know more about swagged cables for tail wires. Especially for the uppers and as a replacement for steamlined wires. If anyone has experience making and using these, please comment!

Thank you so much!

Rob

)

)

Comment