What is the protocol when safety wiring a turnbuckle such as this one where the eye of the 2nd half cannot be accessed? I referenced my trusty AC43.13, but this scenario was not addressed. IMG_1778.JPG

Announcement

Collapse

No announcement yet.

Turnbuckle Safety Wiring Protocol

Collapse

X

-

Turnbuckle Safety Wiring Protocol

Rob Caldwell

Lake Norman Airpark (14A), North Carolina

EAA Chapter 309

Model B Quick Build Kit Serial # 11B-24B / 25B

YouTube Channel: http://bearhawklife.video

1st Flight May 18, 2021Tags: None

-

The control cable itself is twisted and will have internal stress. Loading it over time might increase or decrease that, causing the cable itself to twist more or untwist, plus the eye and turnbuckle it is attached to.

-

I don't think that construction is acceptable under AC43.13.

Either you need to:

1. Use a different turnbuckle type with the barrel lock, or

2. Use a clevis end turnbuckle which you can wire through (this is what I did in slightly different circumstances), or

3. Move the turnbuckle to a different location.

You may be able to wire around the head of that turnbuckle, but I would be concerned about binding depending on how it worked out... Actually, come to think of it, maybe I have done that in one situation. Hard to recall. In that location you ask about, I put the turnbuckle at the other end of the cable and used a clevis end.Last edited by Battson; 05-21-2019, 08:06 PM.

- Likes 1

Comment

-

Always appreciate a different perspective. Makes sense to move the turnbuckle to a inline position. After all, the rudder control cable doesn't have a turnbuckle swinging off the rudder pedal assembly. I'm enlightened! Thanks, Battson!

-

You probably wouldn't want to be wiring a turnbuckle back in the tail, but I suppose that depends on how big your access panels are. Mine are too small. Putting a turnbuckle in the middle introduces an extra two points of failure or snagging. The rudder system does not need any turnbuckles.

-

I had the same question as you Rob. What you have pictured is not acceptable since it can still turn. Next time I’m at the plane I’ll take a look and see how we handled it.Scratch Built 4-place Bearhawk. Continental IO-360, 88" C203 McCauley prop.

- Likes 1

Comment

-

In this picture the wire is missing but you can see where it would go.

image_6048.jpg

Here's one that is only slightly better, but it has the wire at least.

IMG_20170215_163403~2.jpg

Being that the turnbuckle end is not a spherical bearing, the binding risk is lower than I would have first thought.

Also, I would suggest cutting the current wire off and starting fresh. The wire that passes through the central hole should resemble an S rather than a U, if that makes sense. One end going forward and one end going aft.Last edited by jaredyates; 05-21-2019, 10:32 PM.

- Likes 1

Comment

-

My plans call for the AN135 Turnbuckle. But despite some suggestions, I still cannot confidently safety wire the end of the turnbuckle that attaches to the bellcrank. So I think I am going to do as Battson suggests and move my turnbuckles to the rear. I made a nice sized inspection port back there that's much easier to get to over my current configuration, under the floorboards. And I will also change to the clip locking turnbuckle version.

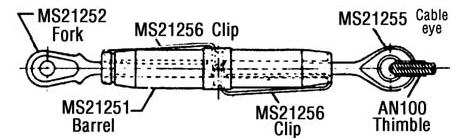

For future reference, the MS21251-B5S Barrel, MS21255-5RS Cable Eye, and MS21256-1 Clip is the replacement for the AN135 Barrel and AN170 Cable Eye. IMG_1779.JPG

Rob Caldwell

Lake Norman Airpark (14A), North Carolina

EAA Chapter 309

Model B Quick Build Kit Serial # 11B-24B / 25B

YouTube Channel: http://bearhawklife.video

1st Flight May 18, 2021

Comment

-

I haven't made it out to the airport yet but I'm quite sure I did very similar to Jared.

Rob, You obviously have a sound decision making process but I think this may be an occasion where you are over thinking things. However, it is nice to have to freedom to overthink things to our heart's continent, I definitely made use of that freedom.Scratch Built 4-place Bearhawk. Continental IO-360, 88" C203 McCauley prop.

Comment

-

All good ideas! Thanks guys!

I have attached the cable ends to the top and bottom of the bell crank and have ordered the clip locking turnbuckles from Spruce that I will install in the tail.

Screen Shot 2019-05-22 at 4.27.08 PM.png

Rob Caldwell

Lake Norman Airpark (14A), North Carolina

EAA Chapter 309

Model B Quick Build Kit Serial # 11B-24B / 25B

YouTube Channel: http://bearhawklife.video

1st Flight May 18, 2021

Comment

-

To safety the turnbuckles in my wings, I adjusted everything and then undid the turnbuckle in the crossover cable. This allowed me to disconnect the other two cables and drop the turnbuckle end down through the inspection hole in the wing out into the open for easy safety wiring. Once put back together, I hooked everything back up and tensioned it all with the crossover turnbuckle which is easy to access and safety.

I would bet the same thing could be done here(as long as the cables aren't "crazy tight"), get everything adjusted, disconnect the cables at the front and rear, fish the turnbuckles out through the inspection panel and safety while out in the open. Getting the final cable reconnected under tension might be a trick but I bet not that tough.....

Comment

-

Instead of releasing tension on the aileron cables with the turnbuckle, it is also very easy to just remove one of the pulleys next to the stick. That releases cable tension and you can pull a pin and safety wire at your convenience. Putting the pulley back in place only takes a couple of pounds of force with the cable tension at 30 lbs (or 24-26). I am using threaded adjusters and clevis forks instead of turnbuckles but you can do the same if you are using turnbuckles.

-

Comment