Hey everyone,

Just wanted to note this here for the record. I have been bothered by issues with my oil cooler supporting bracket.

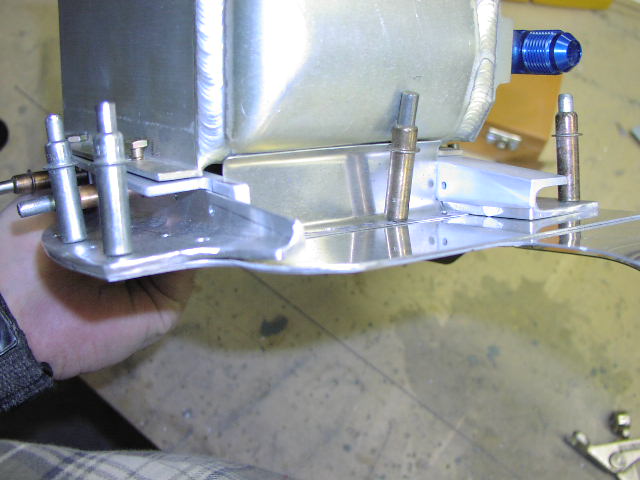

My oil cooler is mounted in the back of the baffle for cylinder #5. The bracket I used to mount it has cracked twice now.

The first time was over 100hrs into service, about 150 I guess, at which point I replaced it with a stronger bit of aluminium. The thicker / stronger metal only lasted about 50hrs, due to lower flexibility I suppose.

Fortunately I used a bracket instead of mounting it straight into the baffle. The second bracket has transferred the stresses to the baffles which are themselves showing the beginnings of fatigue cracking now.

The only solution for me is to move the oil cooler. This is an 11-pass oil cooler sized for an IO-540, so it's heavy and has a lot of heavy oil inside too. Having that much weight shaking around on the engine is simply proving too much for the baffles to take. I know lots of aircraft with smaller oil coolers mount them in the baffles, however this hasn't worked for me.

I considered a firewall mount as a solution, but that means using another aluminium bracket [which I feel like avoiding]. So I will be mounting it straight to the engine mount using adel clamps, and of course running a SCAT duct from the baffle to a diffuser in front of the cooler. I will search down cracks in the baffles, stop drill them on both ends, and add doubler plates.

Hopefully that information helps someone!

Jonathan

Just wanted to note this here for the record. I have been bothered by issues with my oil cooler supporting bracket.

My oil cooler is mounted in the back of the baffle for cylinder #5. The bracket I used to mount it has cracked twice now.

The first time was over 100hrs into service, about 150 I guess, at which point I replaced it with a stronger bit of aluminium. The thicker / stronger metal only lasted about 50hrs, due to lower flexibility I suppose.

Fortunately I used a bracket instead of mounting it straight into the baffle. The second bracket has transferred the stresses to the baffles which are themselves showing the beginnings of fatigue cracking now.

The only solution for me is to move the oil cooler. This is an 11-pass oil cooler sized for an IO-540, so it's heavy and has a lot of heavy oil inside too. Having that much weight shaking around on the engine is simply proving too much for the baffles to take. I know lots of aircraft with smaller oil coolers mount them in the baffles, however this hasn't worked for me.

I considered a firewall mount as a solution, but that means using another aluminium bracket [which I feel like avoiding]. So I will be mounting it straight to the engine mount using adel clamps, and of course running a SCAT duct from the baffle to a diffuser in front of the cooler. I will search down cracks in the baffles, stop drill them on both ends, and add doubler plates.

Hopefully that information helps someone!

Jonathan

Comment