I tried to find an existing topic about this, but couldn't. So I'll start one.

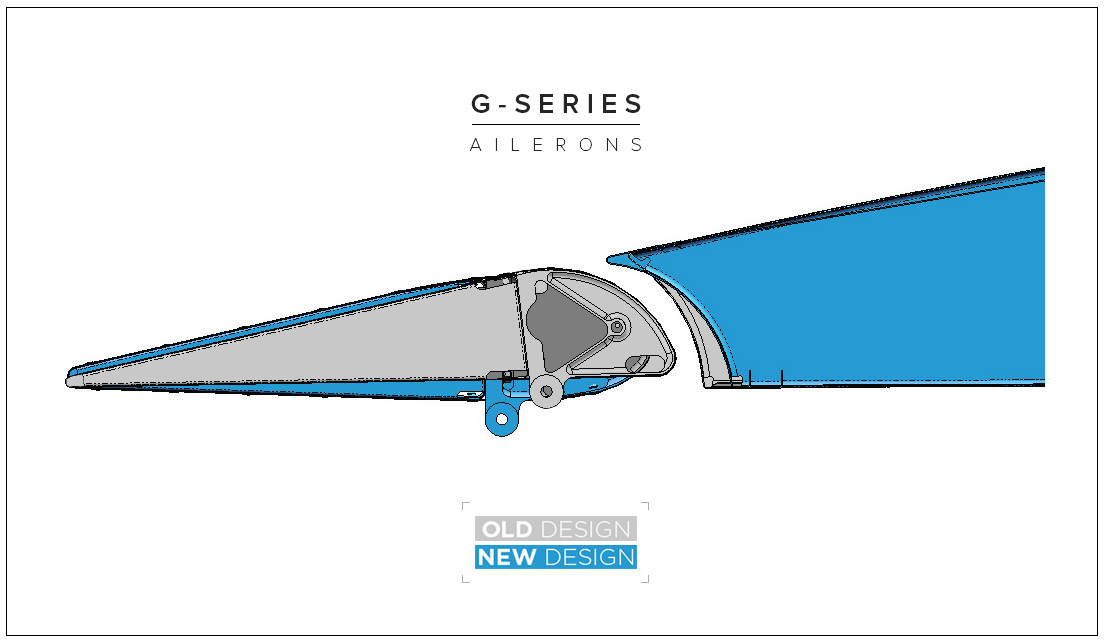

We originally had our ailerons lined up with the flaps and wingtips in flight. In our case, this has them about 1/4 inch below the line of the bottom wing skin, measured at the trailing edge.

The consequence of this, I now realise, was:

On advice from Mark, made a change:

Rigged the ailerons up about 1/4 inch, measured at the trailing edge relative to the line of the bottom wing skin.

With flight air load, this makes more like 1/2" or 3/4" up at the tip, in flight. Visually it's a lot less attractive because it doesn't align with the flaps and wing tips exactly, but it works.

The results are:

We originally had our ailerons lined up with the flaps and wingtips in flight. In our case, this has them about 1/4 inch below the line of the bottom wing skin, measured at the trailing edge.

The consequence of this, I now realise, was:

- heavy ailerons in flight at moderate airspeed

- necessary to use a LOT of leading rudder to initiate rolls.

- high rate rolls are almost entirely done with rudder, ailerons only follow

- very stiff ailerons at high speeds, particularly in dives above Vo where the ailerons are almost locked.

On advice from Mark, made a change:

Rigged the ailerons up about 1/4 inch, measured at the trailing edge relative to the line of the bottom wing skin.

With flight air load, this makes more like 1/2" or 3/4" up at the tip, in flight. Visually it's a lot less attractive because it doesn't align with the flaps and wing tips exactly, but it works.

The results are:

- Aileron control forces nicely balanced with rudder and elevator

- No need for leading rudder during a slow roll

- High speed rolls are a mix of rudder and aileron

- Aileron control forces do not increase in a dive, they remain balanced throughout the airspeed range.

- Overall my Bearhawk feels like a very different (better) aeroplane in flight.

I had forgotten the details of the post and re-discovered when doing a search for aileron rigging. THIS WORKS for the Model A wing for sure. I had discussed a heavy left wing with Mark G and was about to start shimming that when I came back across this post. DESERVES A REFRESH.

I had forgotten the details of the post and re-discovered when doing a search for aileron rigging. THIS WORKS for the Model A wing for sure. I had discussed a heavy left wing with Mark G and was about to start shimming that when I came back across this post. DESERVES A REFRESH.

Comment